About Roll Forming

What is Roll Forming?

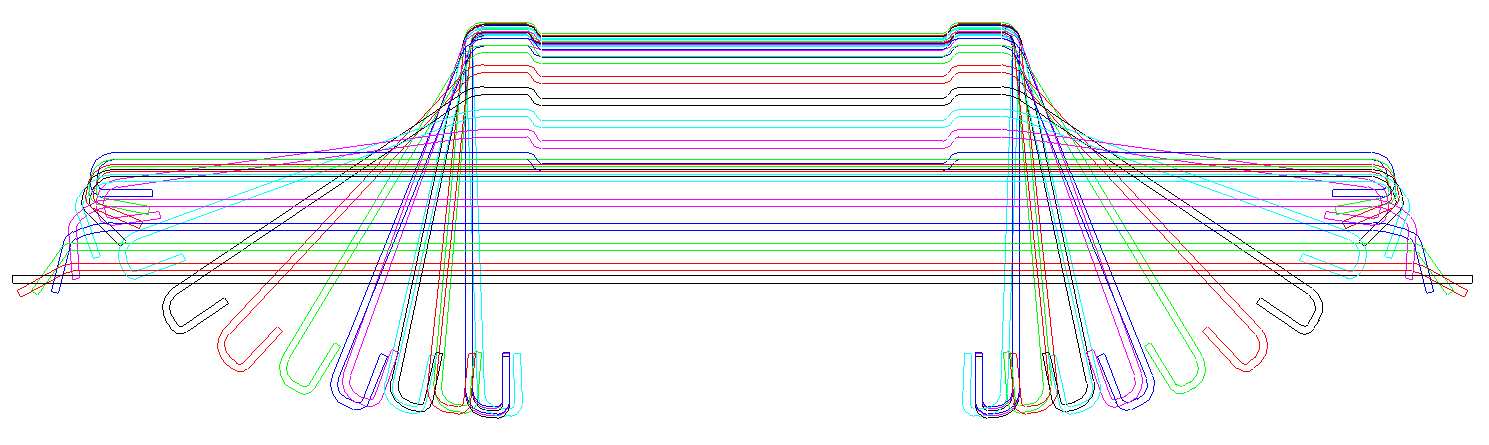

Roll forming is a progressive, metal-fabrication process in which coiled metal is fed through a series of contoured roller dies to form a profile that can be cut to any length. Typical roll-formed profiles include, but are not limited to:

- Angles

- Channels

- Hat Sections

- Box Sections

- Open & Lock-seam Tubing

At Cardinal Manufacturing, we produce all these profiles and more, as well as specializing in the production of custom profiles, rolled to customers’ designs and specifications. We build and maintain our roll forming equipment including tooling, presses and roll forming machines. This allows us to maintain excellent customer service while keeping prices low.

Advantages of Roll Forming

Roll forming has several advantages over other production methods, such as stamping. Costs are reduced by combining several operations into one fast, continuously moving process. Multiple bends, forms, notching and punching can be performed in-line without having to stop between pieces or batches. Better quality can be obtained by ensuring uniformity along the length of the part in addition to the ability to hold tight length tolerances.

High Quality Parts in One Process

Cardinal Manufacturing designs and builds its roll forming machines and associated equipment with the intent of being able to accomplish as many fabrication operations as the customer requires in one, continuously moving process. Our wide range of equipment is built with the latest technology to hold the tightest possible tolerances while performing as many in-line operations as possible while keeping the speed up. To learn more about these operations, visit Our Roll Forming Capabilities page.