Cardinal: Best of Both Worlds

At Cardinal, you have the advantage of working with a manufacturer that has the small-company feel, yet the buying power of an established manufacturer.

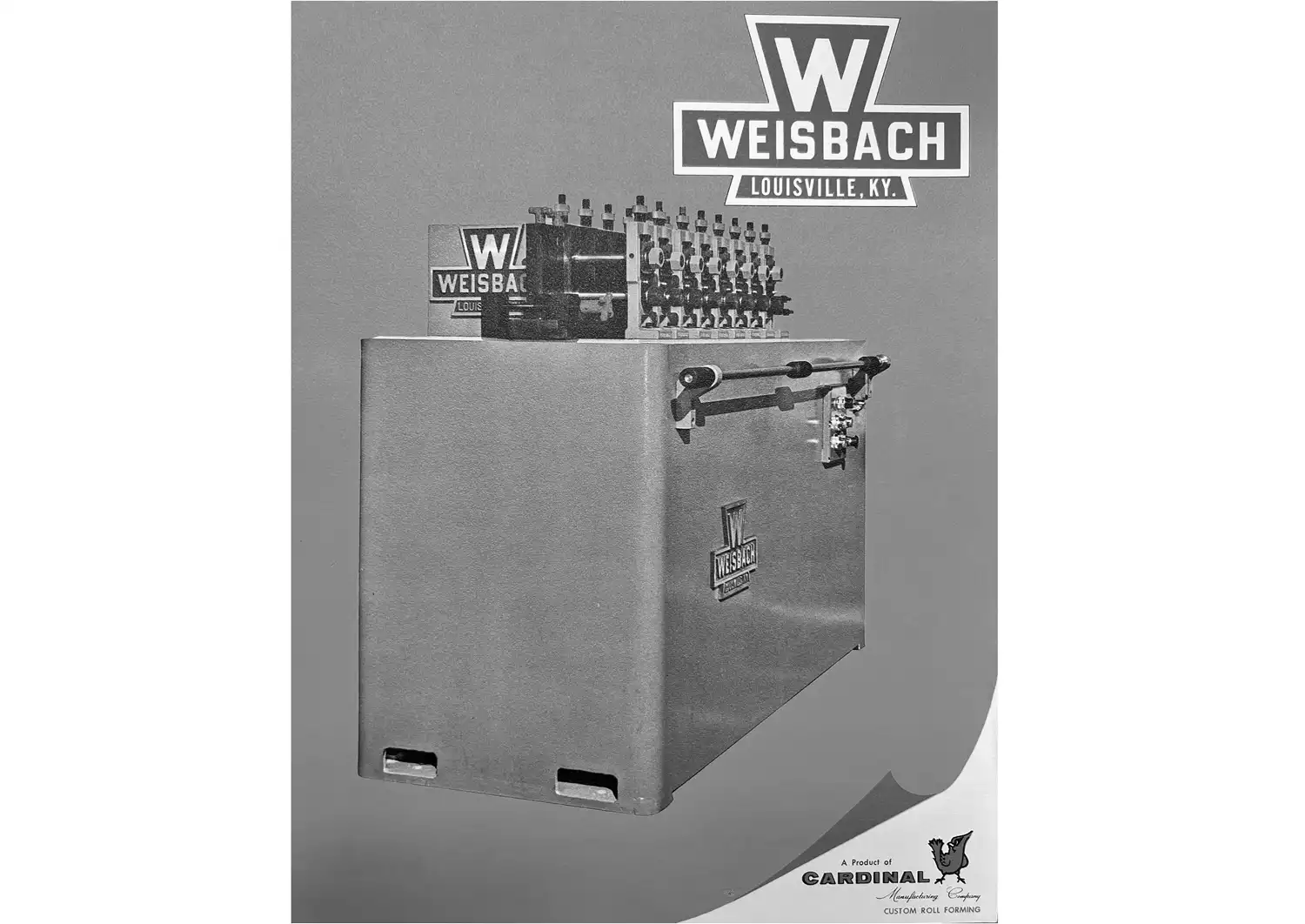

Cardinal History

Since our founding in 1958, Cardinal Manufacturing has been committed to continually producing superior-quality products and providing customer satisfaction with courteous, personalized service. These values were first implemented by Albert Weisbach, who saw an industry need for high-volume productions of small, roll-formed parts and subsequently founded Cardinal in response to that need.

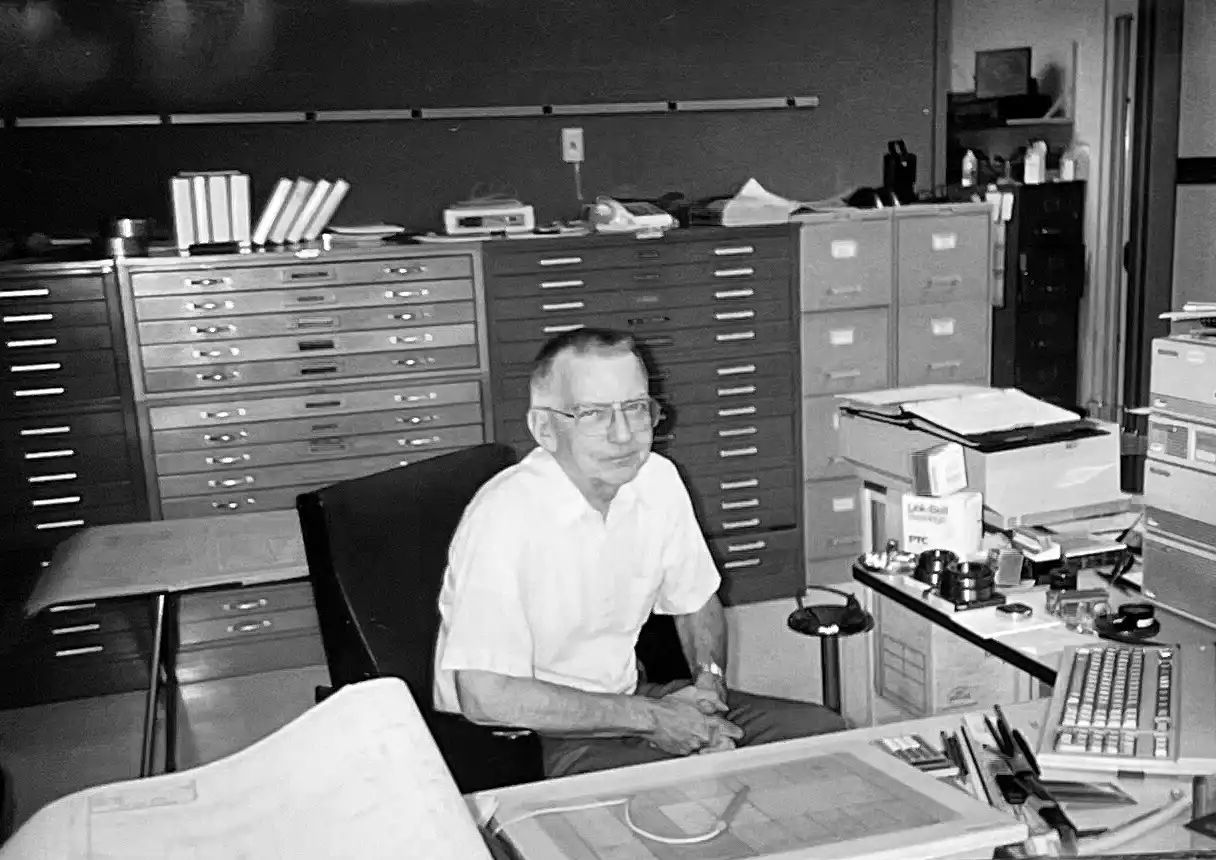

The efficacy of these values speak for themselves—while about 70% of family-owned businesses fail or are sold before the second generation gets a chance to take over, Cardinal has been a successful family company for over 50 years. Not only is this a testament to the quality of Cardinal’s service, but our status as a family company presents a unique advantage. Because company leaders are personally connected and committed to the Cardinal vision, former management still consults with the business and provides their time-tested expertise whenever called upon.

The Cardinal Way

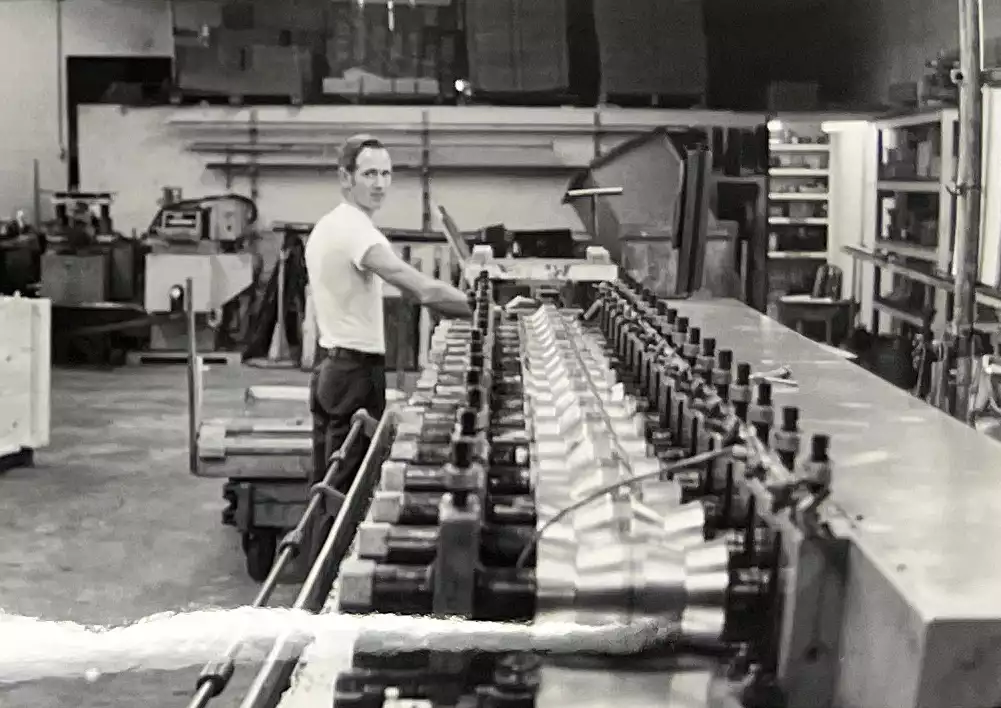

The core of Cardinal’s business is custom roll-forming. Typically, everything we make and sell is the result of a customers’ design and blueprint. We act as a supplier that can bring customer projects to life! Through roll forming services we provide lower operation costs and more efficient production runs, all while delivering high-quality products.

What sets our company apart, in particular, is that we aim to tool each project from the ground up. While we can certainly use existing tooling, we find that our customers tend to prefer to take advantage of our full in-house tool and die shop. Moreover, for any job that we tool and quote, we maintain that tooling for LIFE, which is unheard of in our industry.

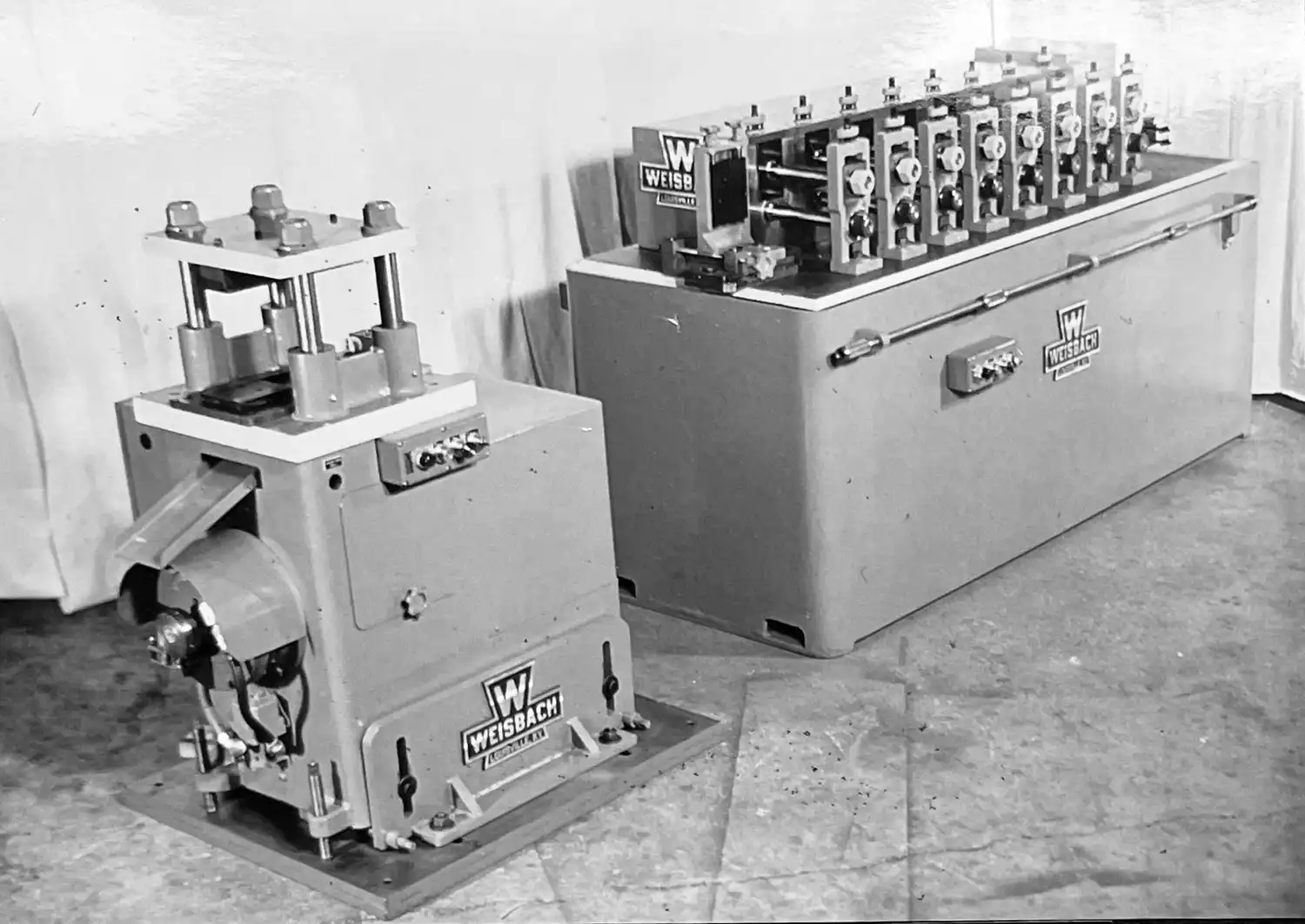

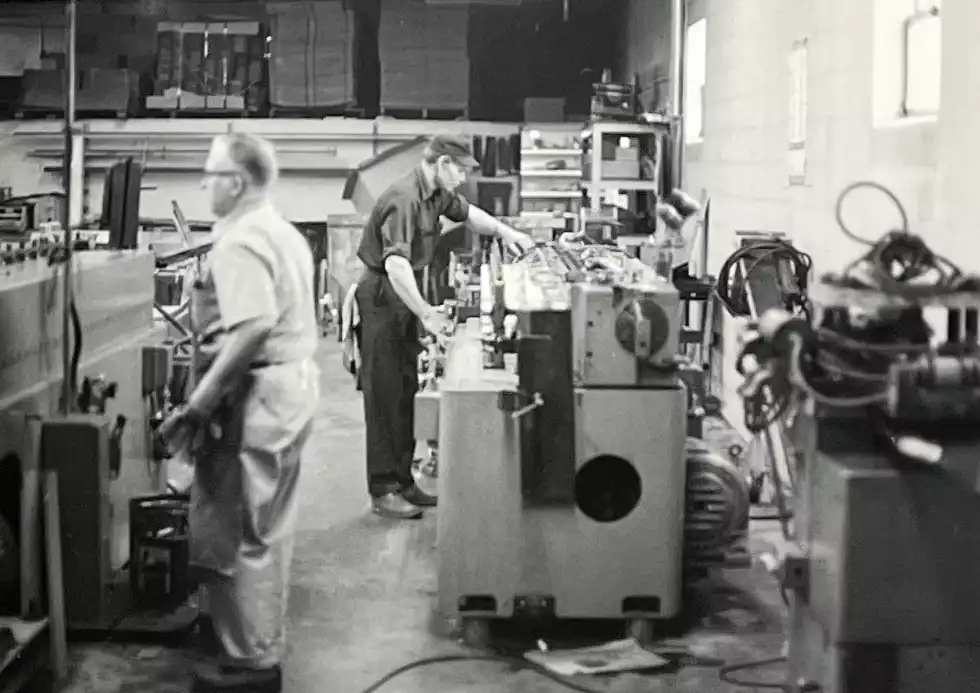

Not only have we made all of our own tooling for decades, we make the majority of all of our equipment. All of our roll forming machines, pre-notch presses, and cut-off presses are made in house, along with many other pieces of miscellaneous equipment used in several of our roll forming lines. We even have several custom, purpose-built secondary operation machines designed and built by our own talented and experienced staff. Because every roll forming machine we use is self-built, Cardinal can easily modify and update machines with new technology and we are prepared for any sort of breakdown, minimizing machine down time.

Outstanding Service

There are a variety of ways Cardinal can price your project, including floating prices based on material indexes, quarterly stocking programs, or discreet, made-to-order purchases. You can rest assured that Cardinal can offer a program that makes the most sense for your project.

At Cardinal, We pride ourselves on our small-company feel, despite large-company capabilities. A big component of that small-company feel is due to communication, which we find to be the key in any successful business partnership. Additionally, Cardinal is known for genuinely caring about our staff, which led to our business gaining an outstanding employee retention rate. Longevity leads to quality consistency, ultimately benefiting our customers further!

We Are Cardinal Manufacturing Not Cardinal Roll-Forming For a Reason

While roll forming is our bread and butter, we also value gradual expansion. Areas such as air filtration have been added to our capabilities over the past few years. Everyone at Cardinal wears a lot of hats and is adaptable to evolving needs because we are a company that is proudly willing to go to great efforts to serve the customer.